The UK and Ireland are currently struggling with a massive under capacity in their requirement for the disposal of municipal solid waste, the treatment of waste water sludge from large municipal/utility operated sewerage treatment plants and more generally, all other forms of biomass waste generated by industry and agriculture.

This has come about due to a prolonged period of under investment by the local authorities, central government and the utilities with little pressure from the regulators to improve this situation. As a result, biomass waste is largely dumped in landfill sites around the country or burned in industrial incinerators and it is clear to all involved that this situation cannot continue. The opportunity is to marry the urgent requirement for a huge increase in waste processing capacity in the UK with the ability to convert the organic cellulose material found in biomass waste into ethanol.

GREE London is helping to develop and exploit with Genesyst UK the commercial potential of the patented GeneSyst International Inc biomass to ethanol process converting biomass (cellulose) to ethanol or other products , which can be used as a petrol additive or fuel substitute. The process is not dependent on food crops such as wheat and corn, but takes commercial advantage of industrial waste (paper and wood high in cellulose), municipal solid waste (after separation of the biomass element), sludge from waste water treatment processes (which are a major problem for the UK & Irish water companies) and other cellulose materials that would otherwise be discharged to landfill changing liabilities to assets.

Benefits of the Process

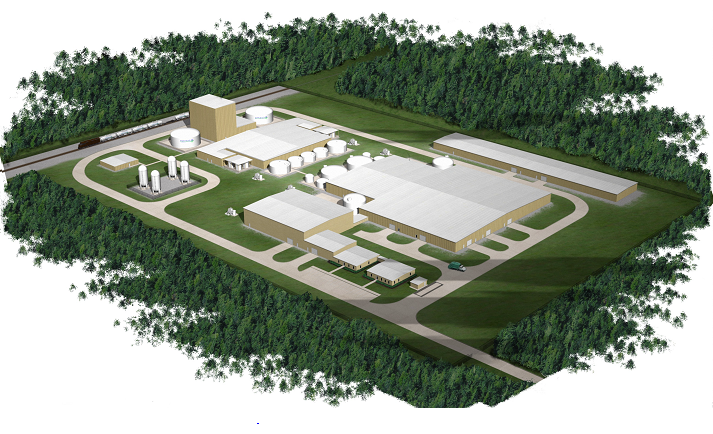

- Minimal capital outlay compared to thermal processes and payback within 3 years.

- Low Visual impact and Small footprint.

- Modular design can be easily extended, replaced, refurbished, maintained and overhauled without shutting down the process.

- The plant will be enclosed to contain and treat odours with minimal emissions and greenhouse gas production: significantly lower than with all thermal or composting processes.

- Flexibility of operation allows for variations in loads, which enables the plant to take additional waste streams from other sources which can reduce gate fees.

- Recognised by the UK Government as suitable for waste treatment and the generation of renewable energy and fuels.

- Ethanol derived from Biomass Waste sources can be used as a fuel substitute, which is carbon neutral and reduces the use of fossil fuels.

- Sludge and Screenings from waste water [sewage] or other effluent treatment plants [septic tank] can be used in the process.

- Additional moisture content of the waste complements the process.

- 95% of Biomass from Municipal Waste diverted from landfill leaving the residue inert and re-usable.

- Option to re-use pre-stored Biomass Waste prior to construction of the plant, which will conserve future landfill space.